The truth about the new SpaceX ‘Mini-Bakery’

Yes, you heard that right! SpaceX has a new mini-bakery! But it’s not feeding all the hungry SpaceX engineers working on the Starship at their Boca-Chica site. Instead, they make their heat shield tiles here.

As Starship prepares for its first orbital flight, the thermal protection system will play a crucial part in making the mission a success.

The SpaceX factory which makes the tiles have been widely rumored around on the internet for many years. But in 2019 we started seeing some SpaceX vans outside, something that looked more like a warehouse in Cape Canaveral, Florida. But oh boy, was it a normal warehouse, in May 2020 there was a site inspection that gave us a much closer look at the new SpaceX facility.

It’s said to have 20 employees at the time of inspection, they run 24 hours a day and they work 7-days a week, in 3 shifts. The facility is said to be about 40,000 Sq.ft in size. The number of employees at the time of writing this blog must have surly gone up as the SpaceX Starship prepares for its first orbital test flight.

So now that we know where they are made, let’s talk about how they are made. The new SpaceX heat shield tiles are very similar to that of NASA’s Space Shuttle’s thermal protection system. They need to be able to withstand very high temperatures during the re-entry. For this, they need to have low thermal conductivity and high specific heat capacity and melting point. Elon Musk has mentioned that the tiles are made out of Silicon and Aluminum Oxide. The tiles are 90% air and 10% Silica and they are a bit like hard form. That’s because Air has a low thermal conductivity and high specific heat capacity. This is very similar to those of the Space Shuttle.

1/2 of the new SN20 is covered with these tiles.

If we take a closer look at these tiles, we can see that they are labeled with red and green stickers.

The tiles with red ones are found to have been broken or damaged somehow during the inspection. The ones labeled in green are found to be misaligned during the fitting.

Now, this might be one of the very first and very important problems for SpaceX to solve. It’s not as simple as baking a few foams like tiles and sticking them on the Starship. For the Starship to be fully reusable, it needs to avoid such inspections. To understand this better, SpaceX plans on reusing the Starship at least three times a day. NASA’s Space Shuttle had a similar technology and it took literal months for inspection and maintenance between launches. The main reason for this is that the Space Shuttle had a much more complex shape than the SpaceX Starship.

The Space Shuttle had many different shapes of tiles, and during the launch ice would fall from the main tank hit these tiles thus, damaging them. SpaceX has about 15,000 tiles compared to 20,000 of the Space Shuttle. The Space Shuttles tiles were glued in place, but SpaceX uses a red robot to weld the mounting pins onto the body of the Starship and a person just comes along and gives it a nice push into place. The reason they choose the hexagon shape is that if they were to go with for example a square shape. then the heat would go between the tiles and the body of the Starship would be exposed to the Starship. The thermal protection on Starship is much more simpler and efficient than compared to that of the Space Shuttle.

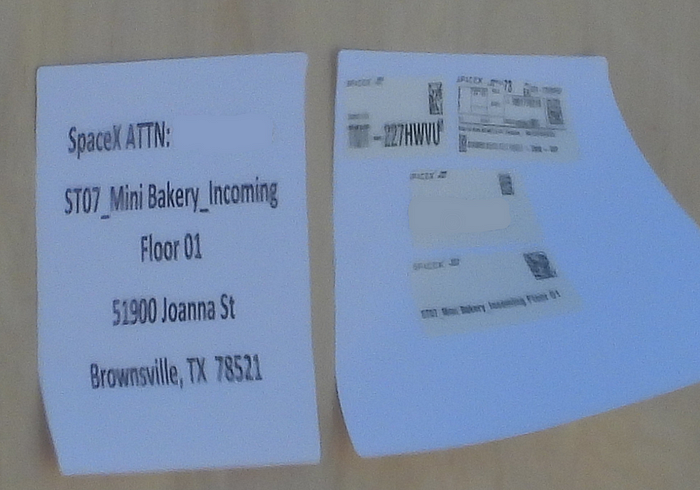

On June 7th 2021 a Boca Chica watcher and Twitter user @StarshipGazer took some really good photos of a few shipments from the so-called “mini-bakery”.

One of them was a wooden crate and was labeled incoming mini-bakery. This could mean that they are moving the mini-bakery, near the production site. Again this cannot be confirmed yet, since it could be some more tiles from Florida as well.

What do you think about new SpaceX ‘mini-bakery’? Let me know in the comment section below!